With the advancements in mining equipment, the trend of mining copper and other profitable minerals has increased in the mining industry. Pure copper has always been a necessary part of one’s life whether it is extracted from primitive mining methods or modern-day efficient equipment. However, the methods used in the past were quite difficult since the laborers’ service was obtained by hand.

The term copper mining generally refers to a range of activities including copper exploration, copper development, copper mine production, copper processing, and copper site reclamation. All these activities contribute to socio-economic benefits whether they take place in northern, remote communities, or urban centers such as Vancouver, Toronto, and Montreal.

Canada has a major role in the production of copper across the world because of its growing demand. Solaris Resources has generated great annual revenue by conducting copper and gold projects in the Americas. Modern technologies and equipment have made it easy to mine copper without much waste and increased chemical exposures during mining stages. The right approach to the processing of copper mining must be learned from Solaris Resources stock, one of the successful copper companies.

Let’s start with the basics of copper mining and processing. Copper mining brings so many advantages in the fulfillment of copper demands. However, it is not an easy process and undergoes the below stages of mining, grinding, concentrating, roasting, smelting, converting, anode casting, and electro-refining.

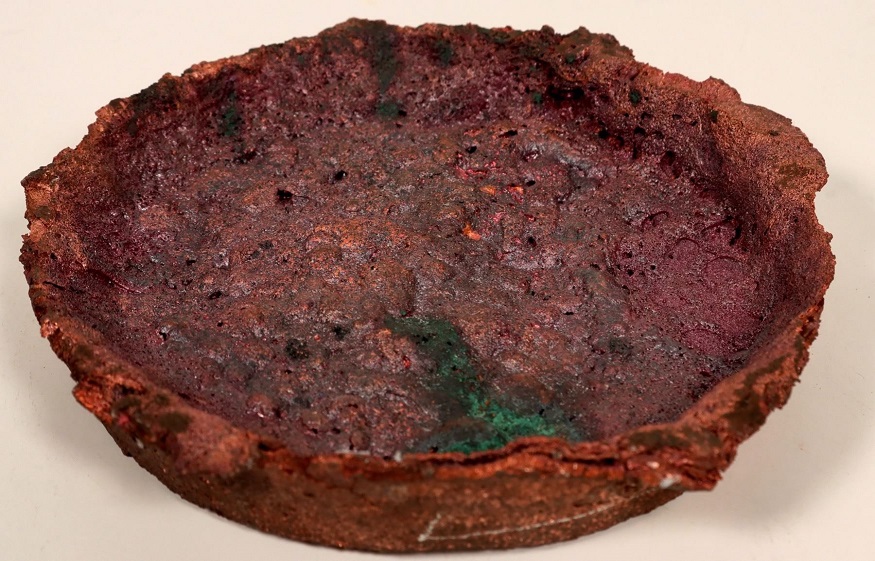

Copper Mining & Processing Copper Ores

Copper – located in the earth’s crust, goes through the following eight stages before turning into a finished product. Then, copper is also recycled to meet around half of Europe’s copper demand.

● Mining

Copper ores are extracted from the ground either by open-pit and underground methods. Mostly, 90% of ore is mined by the open-pit method since no tunnel driving is required.

● Grinding

Copper ores that contain enough copper metal undergo grinding and crushing into powder.

● Concentrating

Then, ores are enriched in this process, and unwanted materials are left behind at the bottom where they are removed. It is also called the froth flotation process.

● Roasting

Chemical reactions take place and enriched ores undergo high temperatures (500°C and 700°C). It removes sulphur as well as dry the ore and makes it a solid called calcine.

● Smelting

In this process, flux is added to make the ore melt easily. The calcine melts at about 1200°C and all the impurities are separated, thus producing a matte. So far, you have extracted 60% copper.

● Conversion

The blowing of air into the liquid matte (mixture of liquid copper and iron sulfide) forms blister copper since gas bubbles get trapped on the surface of the blisters.

● Anode Casting

Blister undergoes anode casting for refining by electrolysis

● Electro-Refining

In electrolysis, copper is purified to 99.99% and it is the last stage towards your finished product.

Conclusion

Copper ores are mined from open pits or underground mining, and these ores containing impure copper are powdered during the process. It is then roasted and smelted to produce matte. From the ores to the finished product containing 99.99% pure copper, the mining undergoes several refining processes.